Our Products

Roebel Bars

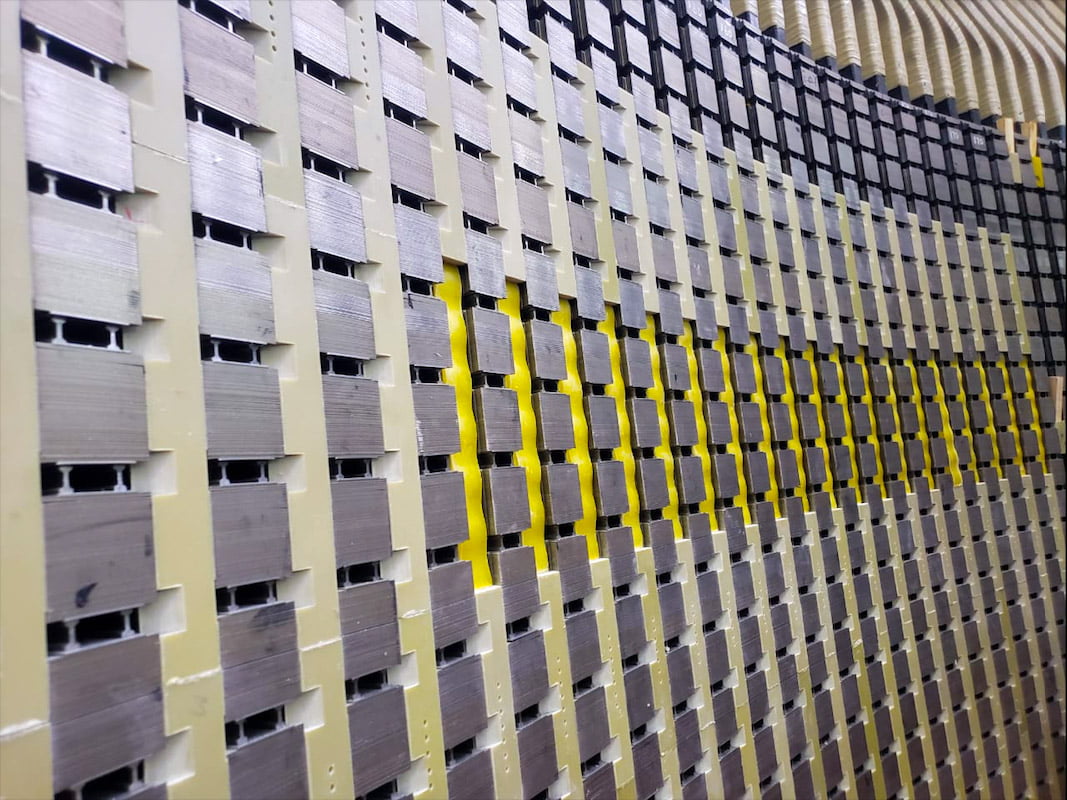

This type of construction is characterized by having the conductors short-circuited at their ends and transposed in part or in their entire length. Each conductor is covered in layers of Dacron and fiberglass. The main insulation is Class “F” and is built from layers of mica tape with epoxy resin. In its straight part, the coils are covered with semiconductor tape, to avoid partial discharges to the slot. At their ends, the coils are covered with a potential grading tape, to avoid surface discharges at the exit of the core.

Multiturn coils / Diamond Coils

We manufacture complete coils of one or more turns, known as Diamond Coils, with Class “F” insulation, up to 20 KV, have a homogeneous insulating system with the same proportion of mica and resin in all its parts, and thus obtain the levels of partial discharges and insulation power factor, which distinguish the quality of our coils, and which allow us to reach the most demanding specifications and tests required by our customers.

Wedges, Fills and Mounting Materials

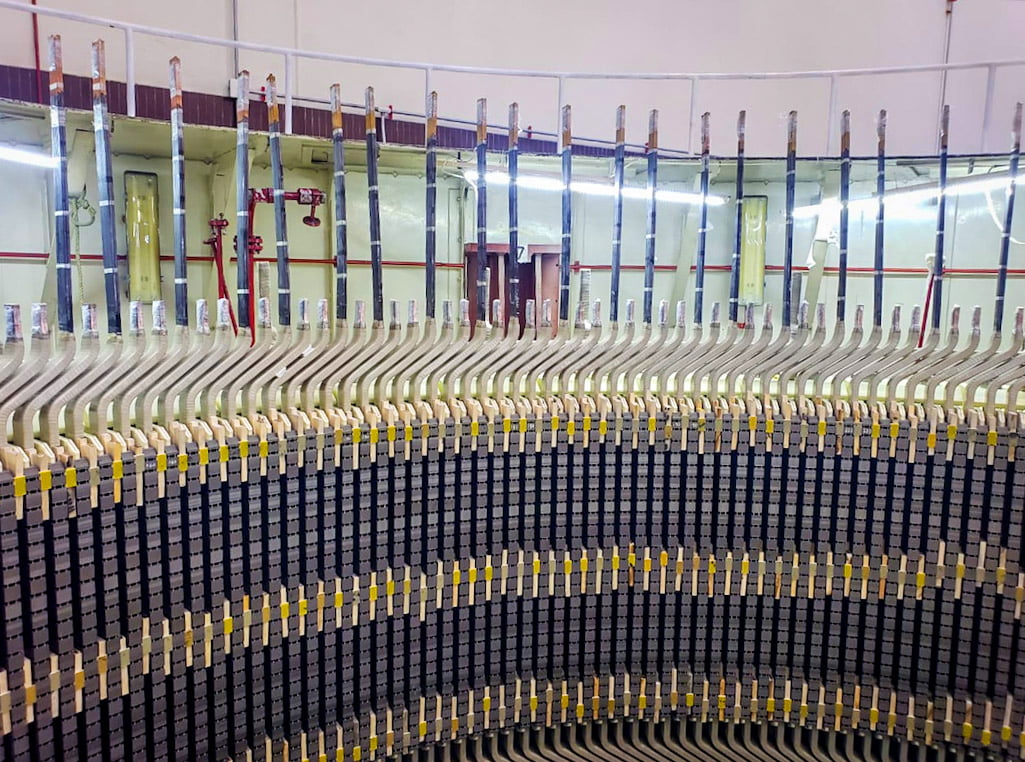

Using fiberglass laminates, with defined shape and prestress, we offer the manufacture of the following parts and components for generator maintenance:

- Wedges for stator slots of all types of Generator

- Flat and Wavy Fills, insulating and semiconductors, for sides and bottom of slot

- Blocks of various geometry used as spacers or supports

For finishes and specific jobs carried out by our clients, we offer the following insulating materials:

- Mica Sheets and Tapes

- Dry and resin laces

- Varnishes and Resins

Rotor Retaining

Rings

Turbogenerator field coils are subjected to big centrifugal forces and must be properly held to prevent catastrophic failure. Its sides are housed in slots in the rotor shaft and are held in place by metal wedges. Its heads are housed in the ends of the rotor shaft, separated from each other by blocks of insulating material and the assembly is held by rings.

These retaining rings are manufactured from forgings of a steel alloy specified by the ASTM A289 standard “Alloy steel for rings for non-magnetic retaining rings for generators”. Due to its composition, this material is known as 18Cr/18Mn steel.

Mounting materials

Using fiberglass laminates, with a defined shape and prestress, we offer the manufacture of the following parts and components for the maintenance of electrical generators:

- Wedges for stator slots of all types of electrical generators.

- Flat and Spring Fillers, insulators and semiconductors, for sides and bottom of slot.

- Blocks of diverse geometry used as spacers or supports.