Our Services

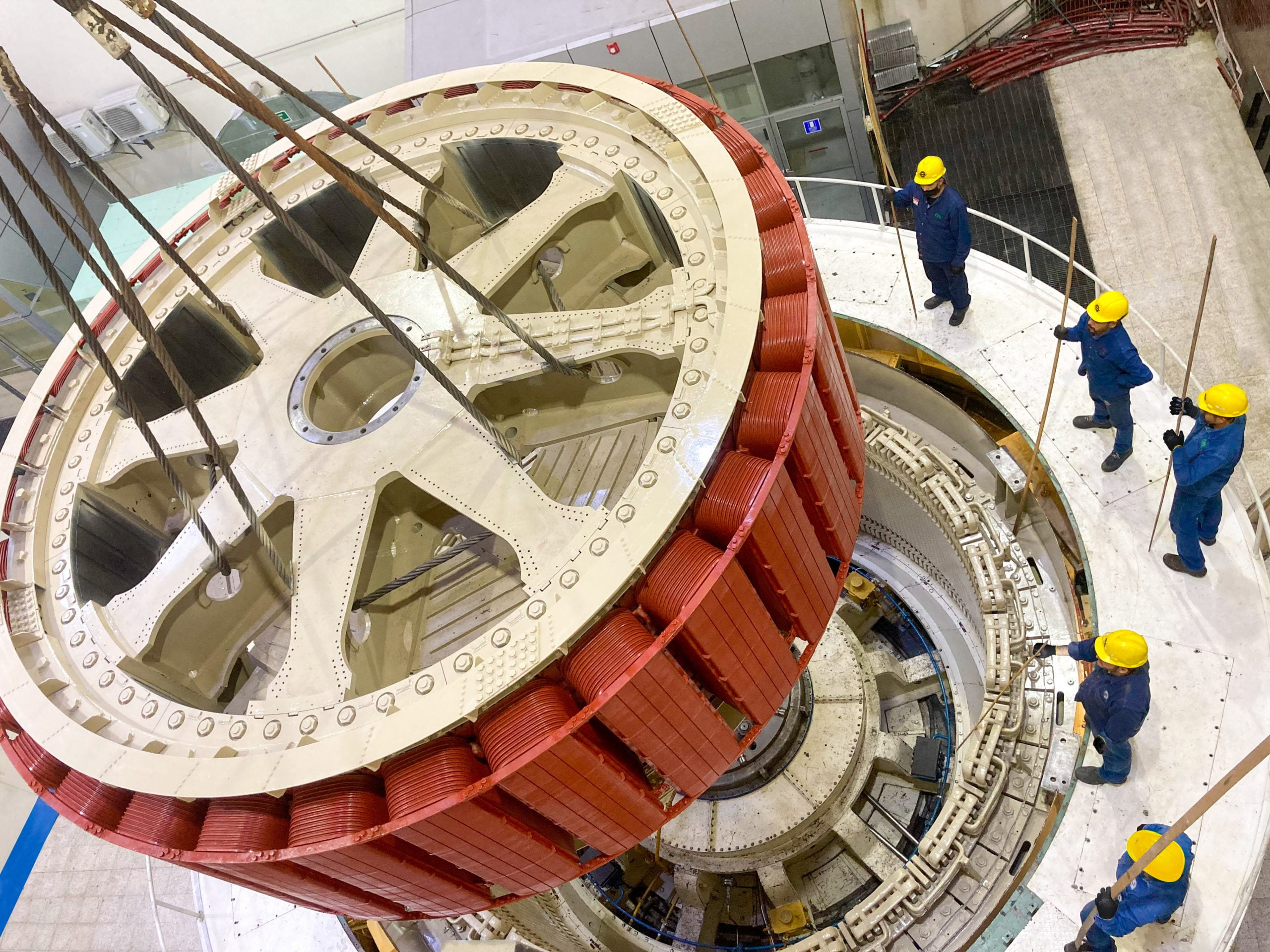

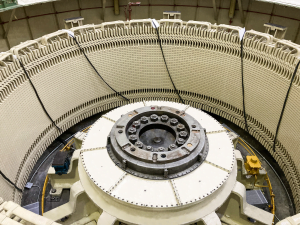

Upgrading and repowering of generators

To repower generators, we offer electromagnetic redesign to achieve this increase in power, thanks to the new technology in insulation systems, their thickness has been reduced, leaving more space for copper to grow inside the slot, which allows for greater circulation of current, coupled with a modification of the lamination within what is allowed by the physical dimensions of the machine, with this it is possible to increase the generation capacity of the generators and their useful life.

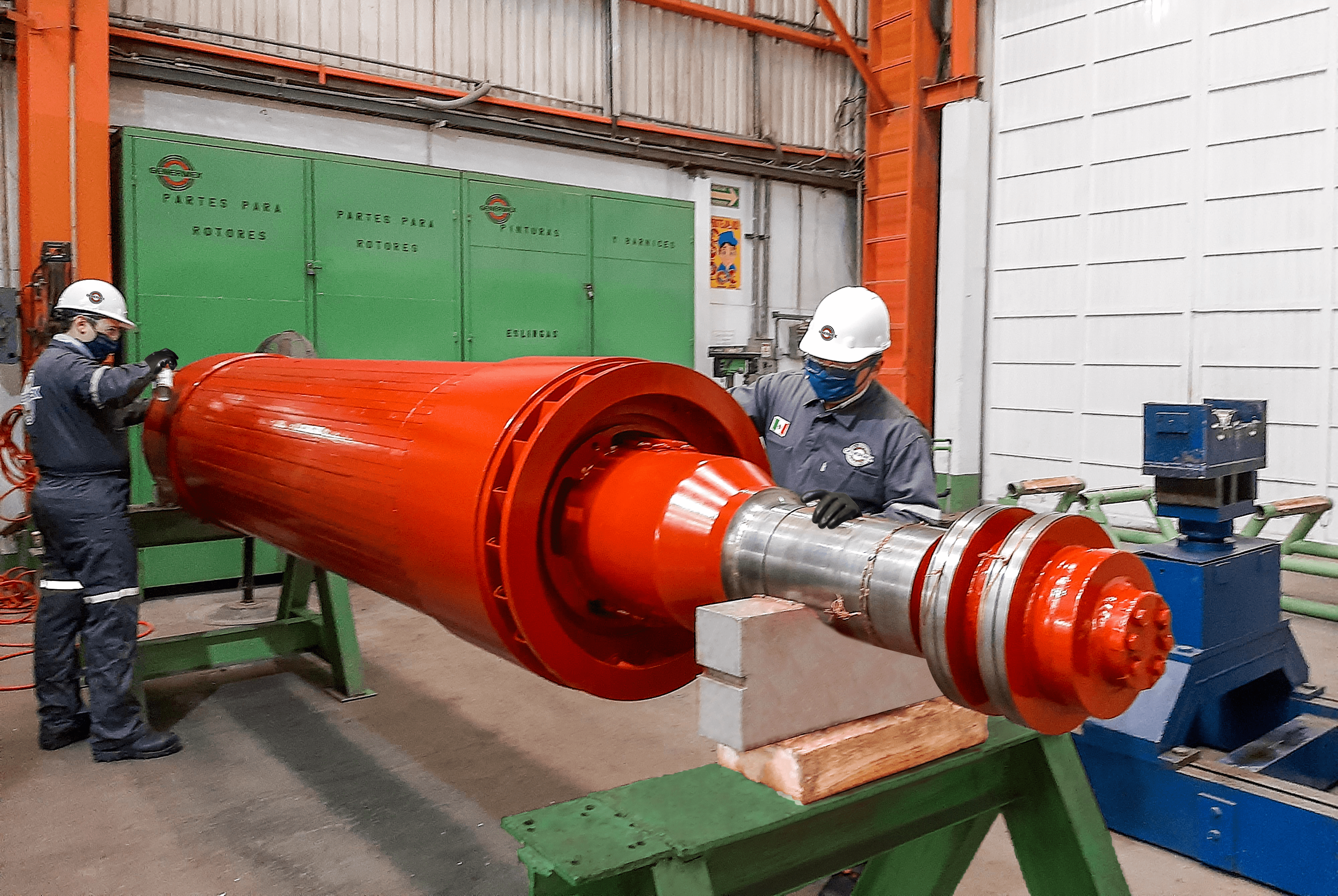

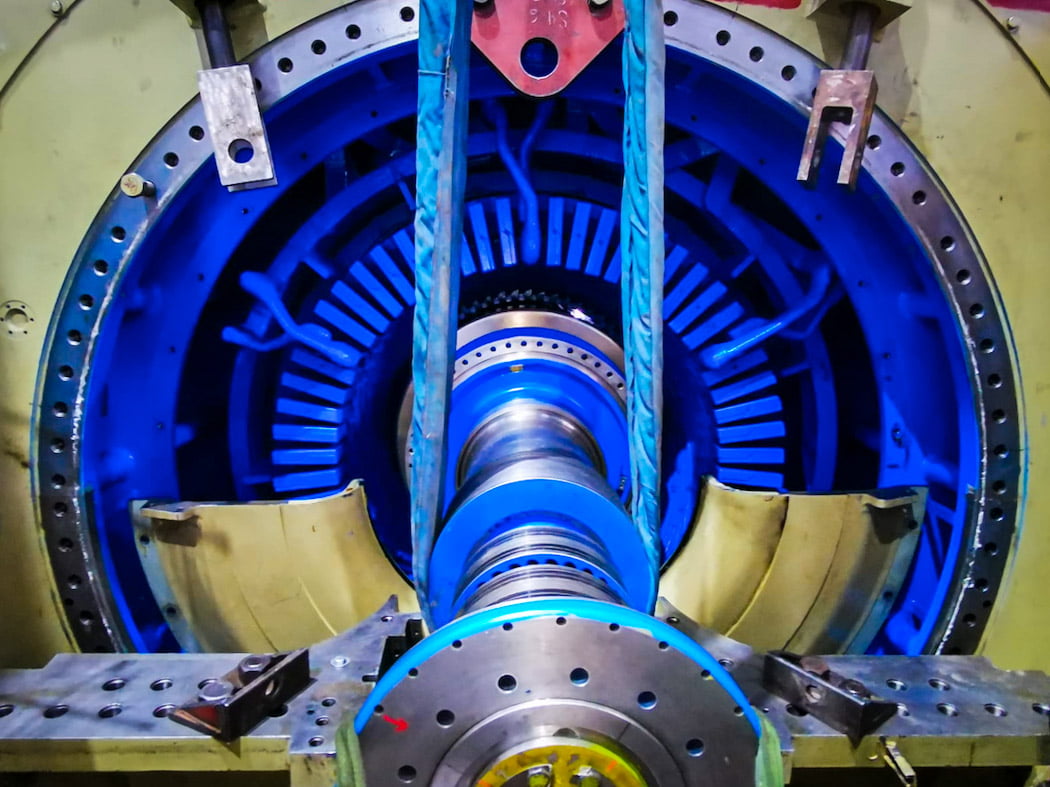

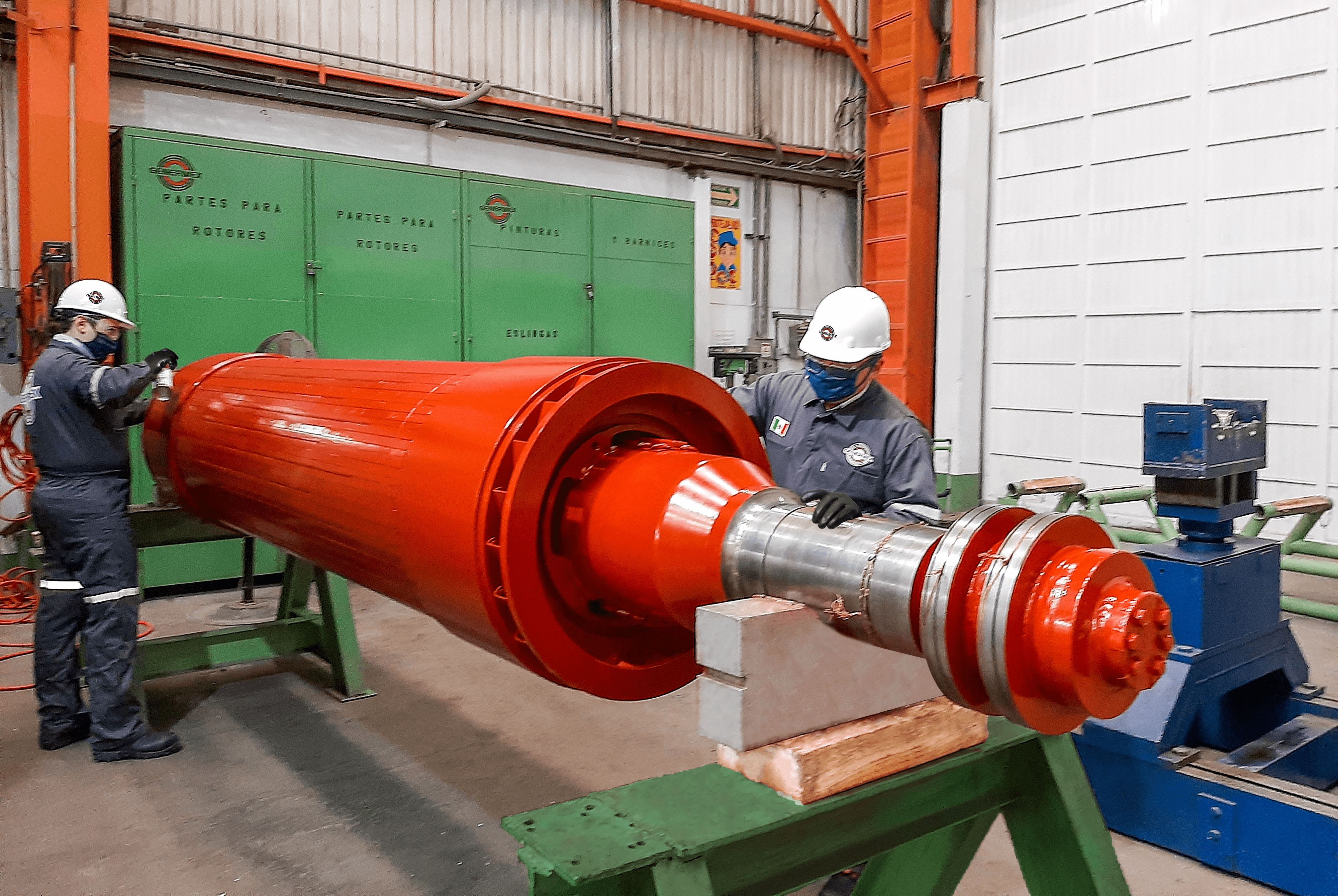

Rotor

Rehabilitation

In flat pole rotors, GENERMEX offers the removal and placement of retaining rings, cleaning and superficial rehabilitation of coil heads, changing spacers, and in case the retaining rings are damaged or in case of If required by our client, GENERMEX offers the supply and installation of retaining rings, fans and couplings or special rotor parts.

In salient pole rotors, GENERMEX offers pole reinsulation and manufacture, if necessary, supply of pole coil separating “V”; blocks.

In both types of rotors, GENERMEX offers the execution of electrical, mechanical, non-destructive tests to the exposed parts of the rotor, as well as the execution of minor works such as polishing of slip rings and journals, rectification of lubrication or seal labyrinths, and the replacement of components such as slip rings, diodes, power lines to the field and dynamic balancing at low speed in banks and at high speed in tunnels.

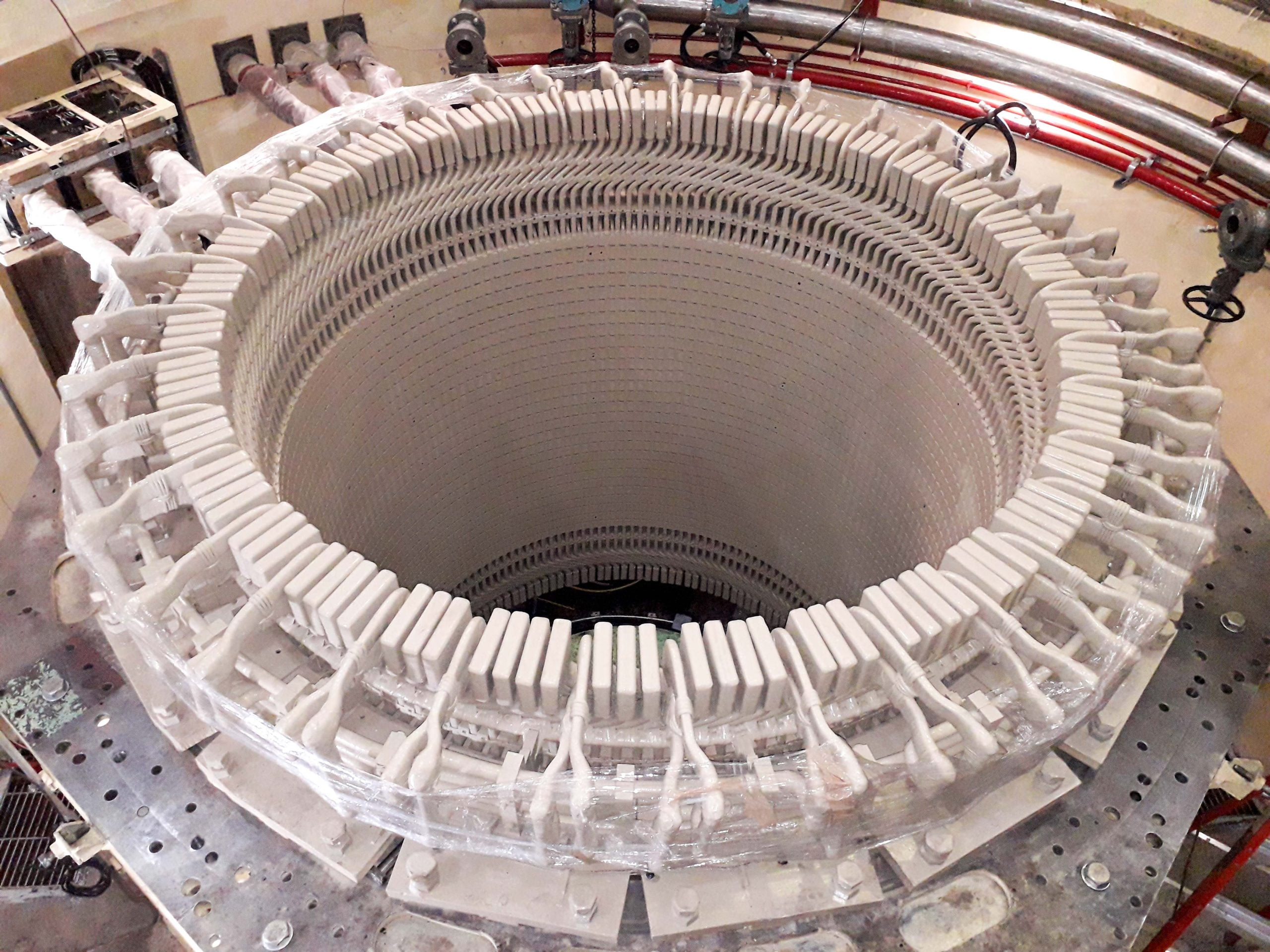

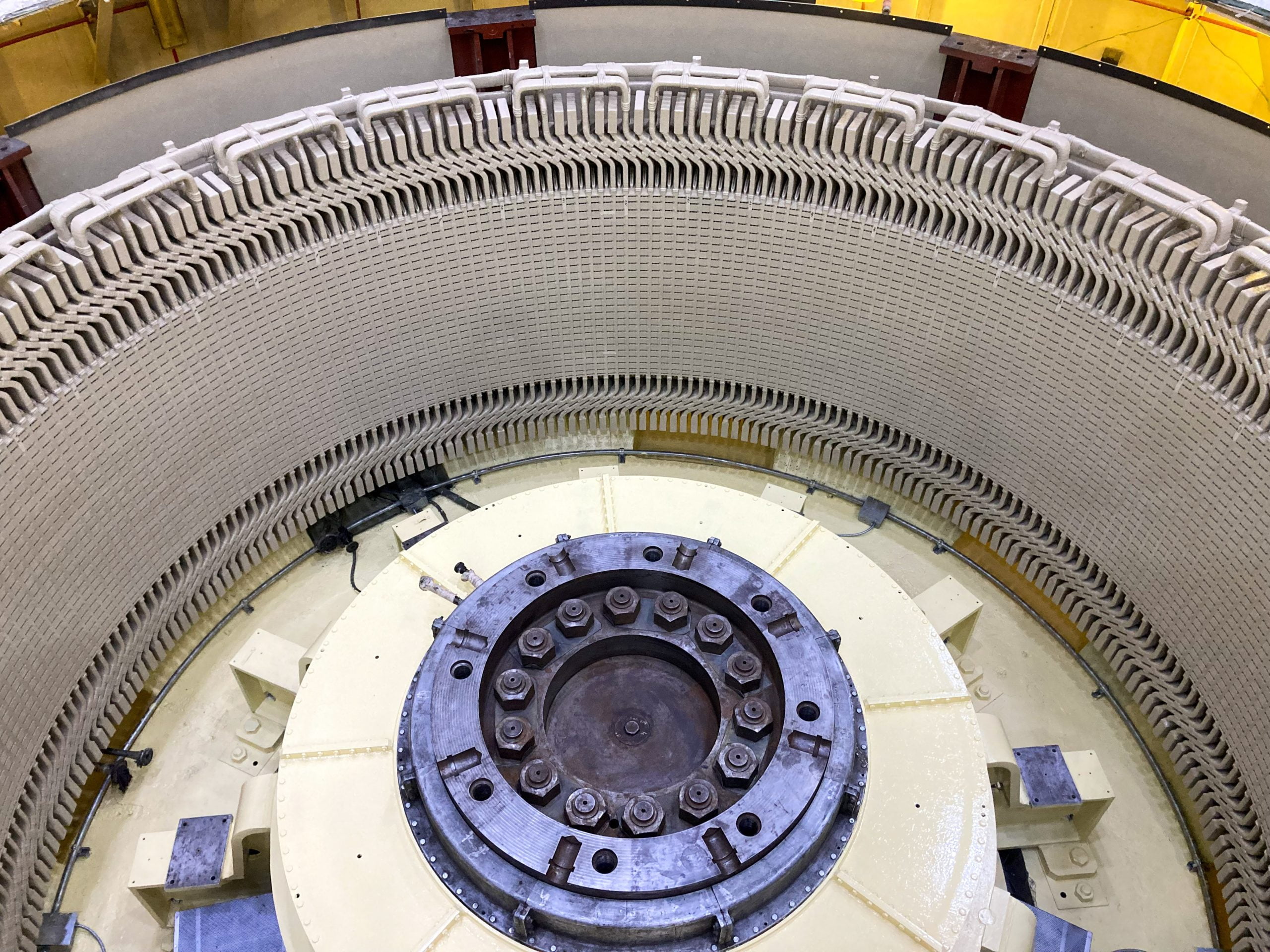

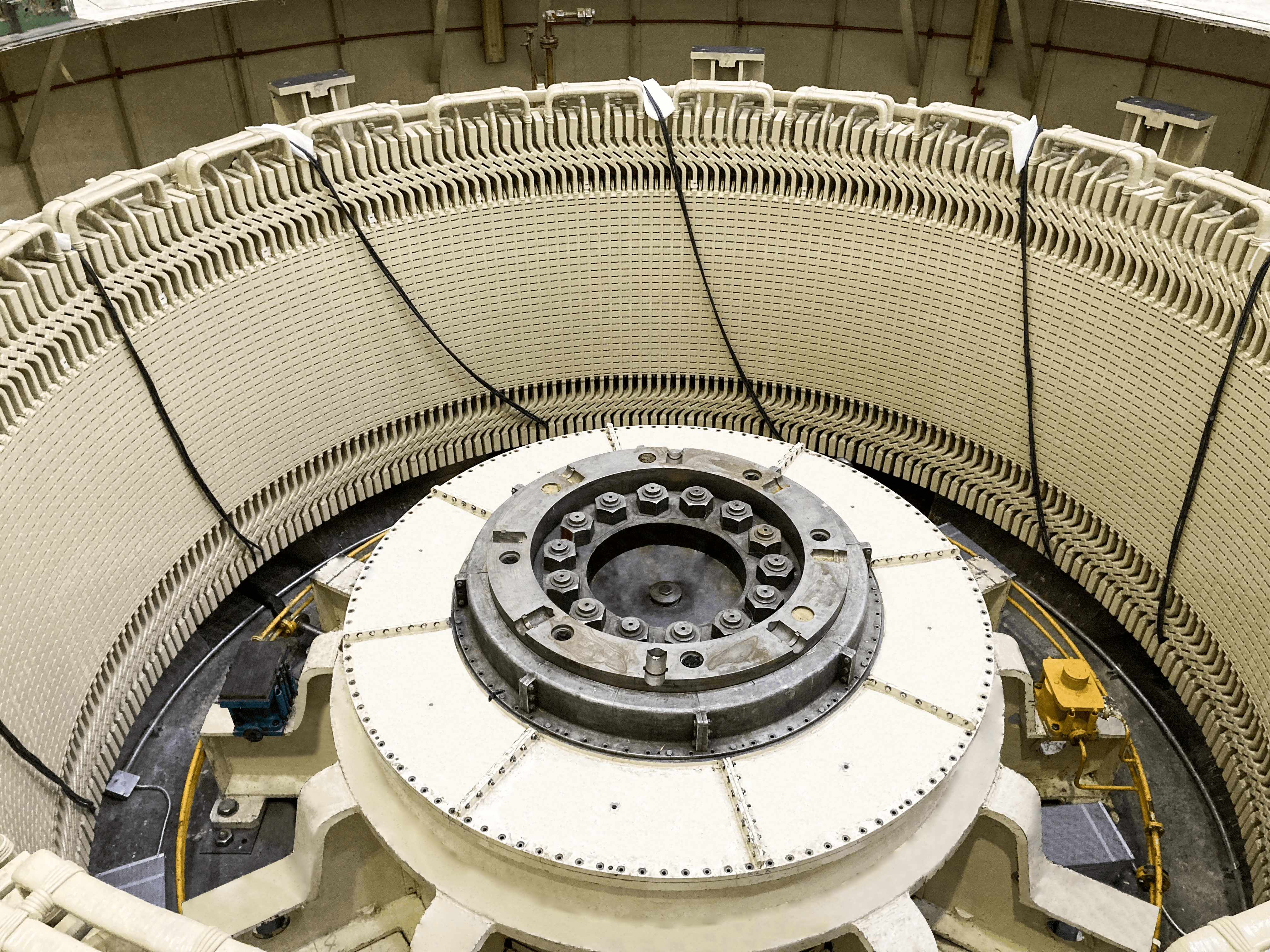

Stator

Rewinding

The rewinding of electric generator stators consists of the removal of the depleted or failed winding and the installation of a new winding.

The design of the new generator coils includes the application of new materials in such a way that, if the original design allows it, the electric generator can get a greater capacity or works cooler and so extends its useful life expectancy.

Repair of cores in generators and

manufacture of parts

In case of major damage to stator cores, GENERMEX offers the supply and installation of lamination packages or complete cores, to replace packages or cores damaged by electrical or mechanical failure. This includes internal laminations, external laminations with welded “I”; bars, pinch fingers, pressure plates and any other components that are necessary to restore or improve the original

clamping, tightening and magnetic characteristics of the core.

GENERMEX offers the continuous stacking technique in core rehabilitation, since this technique allows a better operation of the core avoiding undulations and hot spots in it.

Maintenance of electric generators

GENERMEX offer different types of maintenance for electric generators according to the needs of our clients, understanding that timely maintenance prevents failures in Electric Generators, most failures in an electric generator occur due to operating conditions or to environmental conditions and occur in a transitory process, which is when the mechanical and electrical stresses to which it is subjected are greater, which is why scheduled and constant maintenance is required for electrical generators.

Within the maintenance of electrical generators offered are the following:

- Cleaning.

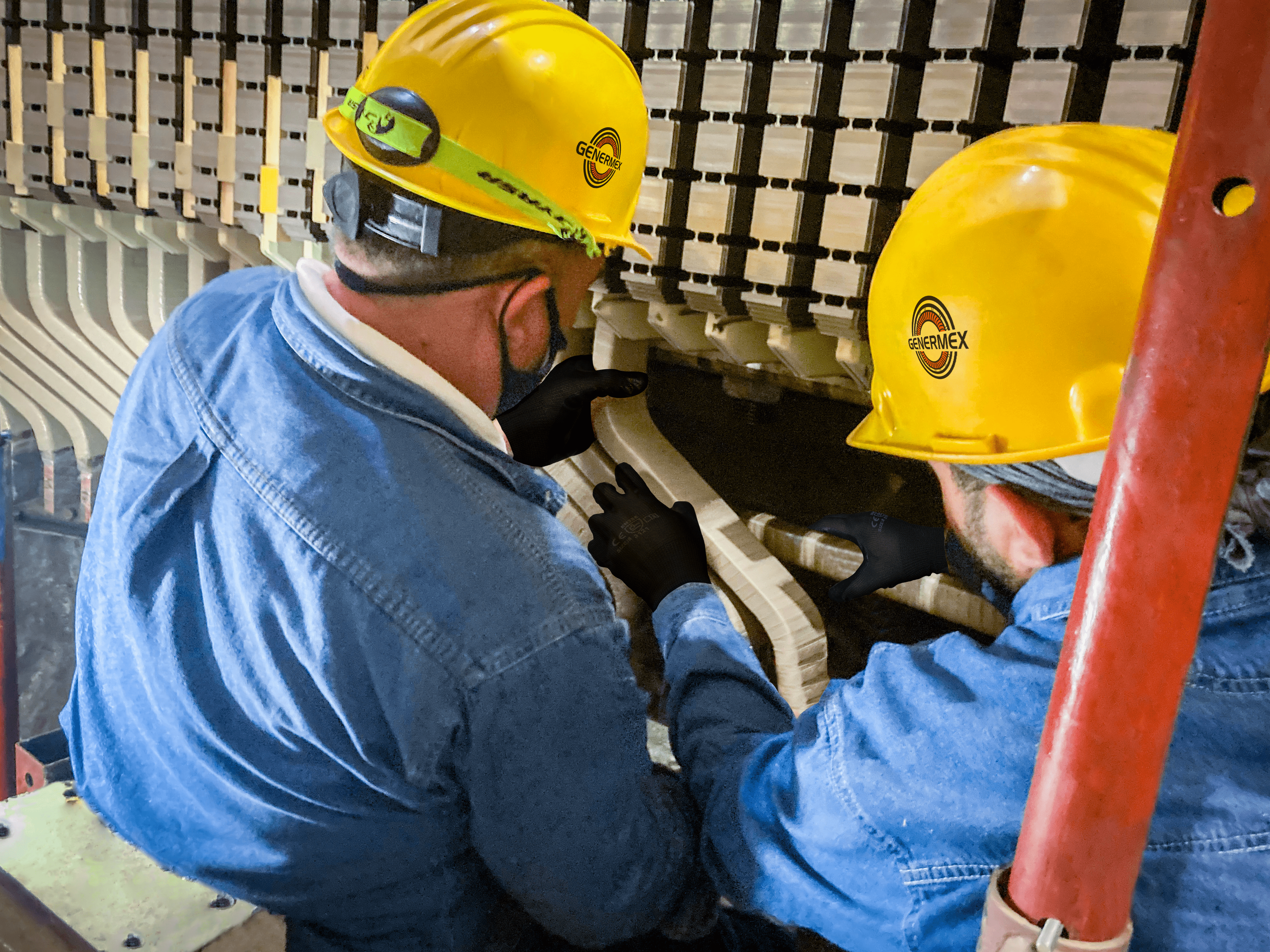

- Change of wedges, separators, and clamping rings.

- Removal, evaluation, replacement, rearrangement and assembly of coils in stator windings.

- Application of paints and tapes of semiconductor material to rehabilitate electric field graduation systems in generators.

- Change of insulation and, if necessary, of coils and field windings in rotors with non-salient and salient poles.

- Minor superficial repairs in stator cores.

- Modification of insulation design to increase the efficiency and, if possible, the power of electric generator

Diagnosis of Generator and

Motor Windings by Visual Inspection and

Electrical Tests

Of all the techniques used to determine the condition of a rotating electrical machine, none is as revealing as a thorough visual inspection by experienced personnel. GENERMEX has extensive experience and specialized human resources to perform visual inspections on generators.

To diagnose the condition of parts and assemblies of a generator, it is necessary to complement the visual observations and the operating experiences, with results of the following electrical and mechanical tests, offered by GENERMEX.

Electrical tests

- Insulation resistance

- Polarization index

- Ohmic resistance to windings

- Power factor and “Tip-Up” to windings

- Partial discharges to windings

- Impedance to rotors

- Voltage balance to rotor poles

- Detection of hot spots in stator laminations

The test known as “ELCID” (Electromagnetic Core Imperfection Detection) allows us to evaluate the state of the interlaminar insulation of the stator core. This test uses little energy and is very effective.

If necessary, it is possible to perform a test that requires high energy and is known as a toroid.

Mechanical tests

- Perpendicularity, concentricity and circularity of couplings

- Perpendicularity, concentricity and circularity of couplings

- Perpendicularity, concentricity, circularity, taper, smoothness, and slip ring groove depth

Electrical testing for generators

- Of all the techniques used to determine the condition of a rotating electrical machine, none is as revealing as an inspection thorough visual by staff experienced. We have wide experience and specialized human resources to carry out visual inspections and tests on electrical generators.The test results allow us to know the state of the isolates in stator coils, rotor and core; the semiconductor structures that alleviate and graduate efforts of electric field; the fastening systems of the windings that prevent their vibration and wear; the ventilation and cooling systems; the connections and electrical contacts; and the laminations of the electromagnetic core, among other components of the generator.With these results we can decide if a generator is in safe and reliable operating conditions.

ELECTRICAL TESTING

Stator Tests:

- Insulation Resistance and PI Test

- Winding Resistance Test

- Power Factor and Tan Delta Test

- Partial Discharges Test

- Slot Partial Discharges Test

- Verification of Corona Effect with UV Camera.

- Wedge Tightness Detector Test

- Bump Test of windings

- Electromagnetic Core Imperfection Detection (ELCID)

Rotor Tests:

- Insulation Resistance and PI

- Winding Resistance Test

- Impedance Test

- RSO

- Voltage Drop Pole Test

Rotors overhauling

- In both non-salient pole and salient pole rotors, we offer re-insulation of polar coils by changing the insulation between turns and insulation to ground.In both types of rotors, we offer the execution of electrical, mechanical, non-destructive tests to the exposed parts of the rotor, as well as the execution of minor works such as polishing of slip rings and journal bearings, rectification of lubrication or seal labyrinths, and the replacement of components such as slip rings, diodes, power lines to the field and dynamic balancing at low speed in benches and at high speed in the tunnel.

Lamination changing of stator core

- In case of major damage to stator cores, we offer the supply and installation of lamination packages or complete cores, to replace packages or cores damaged by electrical or mechanical failures. This includes internal laminations, external laminations with welded “I” bars, clamping fingers, pressure plates and any other components that are necessary to recover or improve the original clamping, tightening conditions and magnetic characteristics of the core.For the assembly we use the continuous stacking technique in core rehabilitation, since this technique allows a better operation of the core avoiding undulations and hot spots in it.

Training

We offer a Course on Electric Power Generators, oriented towards the maintenance of electric generators. The Course is divided into Modules, each of which can be taught in one or more sessions, depending on the needs and possibilities of the personnel concerned.

This Course seeks to identify and assimilate the technological knowledge associated with the electric generators that our clients operate and maintain. This to help them improve their continuity, reliability, security and cost rates.

The content of the Course can be synthesized into four specialty areas:

- Design and Construction of Electric Generators

- Efforts in its parts and materials, derived from the particular characteristics of its actual operation.

- Electrical Testing and Acceptance Values

- Proven actions to extend the useful life of electric generators

![20211028_142723[97] copia](https://genermex.net/wp-content/uploads/2021/01/20211028_14272397-copia-scaled.jpg)

![Capacitación Guatemala2[60]](https://genermex.net/wp-content/uploads/2021/01/Capacitacion-Guatemala260.jpg)

![20211028_161415[30] copia](https://genermex.net/wp-content/uploads/2021/01/20211028_16141530-copia-scaled.jpg)

![20211028_142723[97] copia](https://genermex.net/wp-content/uploads/2021/01/20211028_14272397-copia-225x300.jpg)

![Capacitación Guatemala2[60]](https://genermex.net/wp-content/uploads/2021/01/Capacitacion-Guatemala260-300x225.jpg)

![20211028_161415[30] copia](https://genermex.net/wp-content/uploads/2021/01/20211028_16141530-copia-300x225.jpg)